Like many other industries, heavy construction organizations face pressure to increase their operational efficiency and profitability. This latest round of pressure is due to the passage of the $1.2-trillion Infrastructure Investment and Jobs Act (IIJA). This legislation is earmarked to rebuild roads, bridges, ports and airports, upgrade public transit and rail systems, replace lead pipes to provide clean water, clean up pollution, provide affordable high-speed internet to every family in America and deliver cheaper and cleaner energy.

A sudden influx of work means growth. But with a lack of available qualified workers, contractors are forced to focus on productivity improvements, since a heavy equipment operator isn’t exactly an entry level position. The obvious but challenging advances are improving machine duty cycles and faster cycle times. Unfortunately, the needed gains will require more than working harder and faster can deliver. So, what is the answer?

Technology. The industry has already made significant efforts at implementing high-precision machine control, and many large contractors plan to continue investing in this arena. But many leaders in the industry are unsure where to invest next. Kinetic Mesh private wireless networks on jobsites are exactly where.

No one in the modern world would debate the value the internet has brought to businesses over the last four decades—not just ease and accessibility from online shopping and search engines, but also the connectivity of electronic communications around the globe via email, instant messages, video conferencing and data sharing. However, a lack of reliable connectivity on jobsites is stalling the collaboration of construction employees and the improvement of condition-based machine maintenance.

Connectivity is the enabling foundation for all technological productivity. This is a fundamental truth. Denying or ignoring this fact will not change the importance of reliable connectivity. Output Equipment Manufacturers (OEMs) and technology pioneers in the construction industry are investing huge sums to develop autonomous or tele-remote technologies to improve overall jobsite optimization. These technologies require mission-critical communications, though. Once that foundation is implemented, benefits abound including improved worker communications, reduced survey time, minimized equipment wear and tear, increased jobsite security and optimized overall productivity.

Deploying mission-critical high-bandwidth communications to support jobsite technology does come with its own challenges such as evolving topography and unmovable structures. Operators need to implement a reliable network to overcome the connectivity issues posed by a challenging environment to achieve a connected jobsite.

IMPROVING EFFICIENCY WITH ADVANCED TECHNOLOGY

Whether building sewers, roads, highways, bridges, tunnels or undertaking other large government and city projects, heavy construction sites are inherently complex. The industry has evolved over the last decade to become much more high-tech, growing from $1840.28 billion in 2022 to $1936.17 billion in 2023 at a compound annual growth rate (CAGR) of 5.2%.

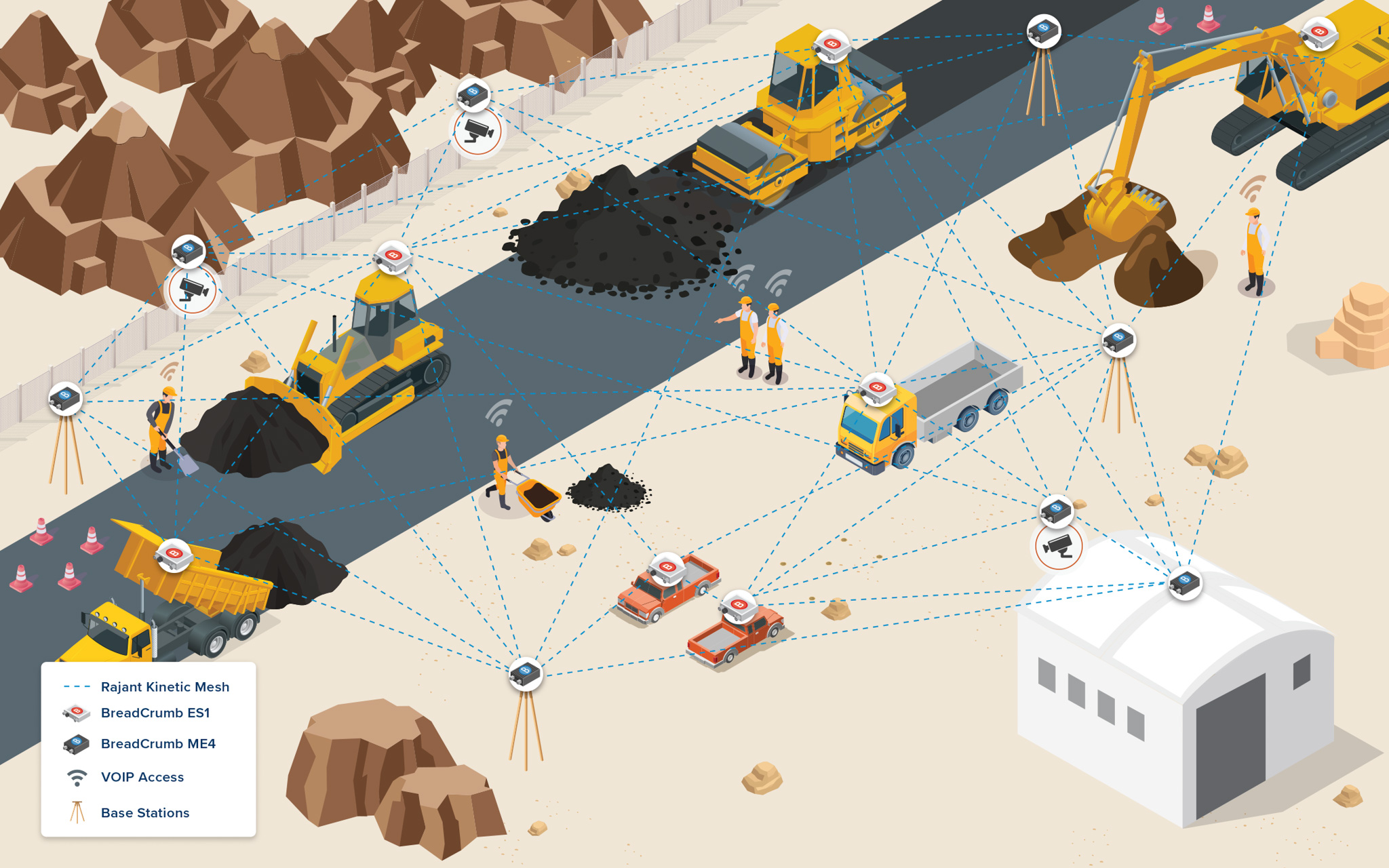

Heavy construction sites have base stations and machine control on dozers, road graders and asphalt pavers. This machinery’s real-time telemetry and other data demands often exceed what traditional serial radios, Wi-Fi and LTE can support. The future demands of tele-remote and autonomous machines are even greater. Machine health monitoring, real-time video streaming and consistent M2M communications are dependent on a robust network to transform machine control, worker safety and jobsite security. Easily deployable wireless networking that can adapt to the environment without high-tech specialized support is equally important to jobsite productivity.

RELIABLE CONNECTIVITY ON SITE

The network can often be the downfall of operations if it cannot provide the reliable connectivity a jobsite needs. Infrastructure projects often require multiple base stations for high-precision earthmoving. Suppose an organization is currently using a serial network for corrections. In that case, they are limited to a base radio, a single radio repeater and a machine radio, which severely limit the range in which the organization can receive corrections before adding another base station. Additional base stations can create additional survey grids, which increase the risk of grade mismatch.

If machine control-enabled machines are connected to a base via Wi-Fi, those machines will have an even smaller operating range and run the risk of losing connection as they roam across a site. LTE also has challenges. Despite the great coverage maps that cellular carriers publish, many jobsites have poor to no coverage and even when there is coverage available the construction site still has no control over network congestion.

A MISSION-CRITICAL NETWORK IS A MUST

A Kinetic Mesh network is easily deployable and rapidly scalable to expand base station range in any direction while also providing high data and continuous connectivity throughout for numerous efficiency-transforming site applications. It also keeps applications running that enhance overall safety, enable surface condition surveying and speed up construction productivity.

This means that heavy construction operators can solve a core challenge many jobsites face with greater base station range and additional bandwidth so new applications can be enabled. Within the network, BreadCrumb nodes have an integrated Wi-Fi service for compatibility with virtually any commercial Wi-Fi device, such as laptops, tablets, smartphones, IP cameras, sensors and other IP devices. Reliable Wi-Fi is necessary for cloud-based project management tools. It can also be used for either Wi-Fi calling via employees’ existing cell phones or radio over IP if Wi-Fi two-way push-to-talk radios are available.

A Kinetic Mesh network performs reliably even in areas with varied terrain, like rolling hills or dense foliage that are prevalent in heavy construction operations, because Rajant BreadCrumbs autonomously manage data routing around obstructions and local interference. Any piece of machinery becomes part of the network and that makes the network much more dynamic. It will also improve connectivity in motion and around obstruction.

In addition to real-time communications, the network supports livestreaming video surveillance, machine telemetry and sensor insights from equipment collecting data on potentially dangerous and expansive construction sites. As a result, the corporate office now has instantaneous oversight into an operation’s status as it occurs.

FLEXIBLY ESTABLISHING AND EXTENDING CONNECTIVITY

The introduction of digitized modern technology has helped the heavy construction sector make a significant step towards more efficient operations. But it now needs to take the next step: connecting these devices with the desired applications via a reliable network. Construction sites require a connection that expands coverage for base station corrections, remotely loads machine guidance models, improves productivity and enables the streaming of video surveillance. Connectivity of this type ensures OSHA compliance, equipment theft reduction and elimination of site vandalism.

Network connectivity is mission-critical in heavy construction projects. Rajant Kinetic Mesh is a private wireless network that gives heavy construction jobsites a better network alternative. With the capacity to create networks with less reliance on fixed infrastructure, Kinetic Mesh allows operations to flexibly establish and extend connectivity in challenging environments, enabling data, voice, video and autonomous applications where needed.