Disrupting the Future of Construction Soundproofing

Construction soundproofing continues to be one of the most misunderstood and frustrating elements of building and construction, especially in the multifamily and hospitality industries. There are always questions about when and how sound blocking options, sound masking technologies and consulting services should be used. Misinformation about the implementation and effectiveness of these solutions can significantly change profit margins and sound transmission classification (STC) rating compliance.

For years, the primary solution used to achieve STC ratings has been gypsum, particularly in unit-to-unit multifamily construction. However, as gypsum prices continue to increase, the cost of simply double- or triple-stacking layers becomes less enticing and even unsustainable.

According to the Federal Reserve’s Economic Data, the producer price index of gypsum product manufacturing has increased by 73.2% since 2010, and it reached a peak increase of 83.1% in September 2018, a trend which is expected to continue in the near future.

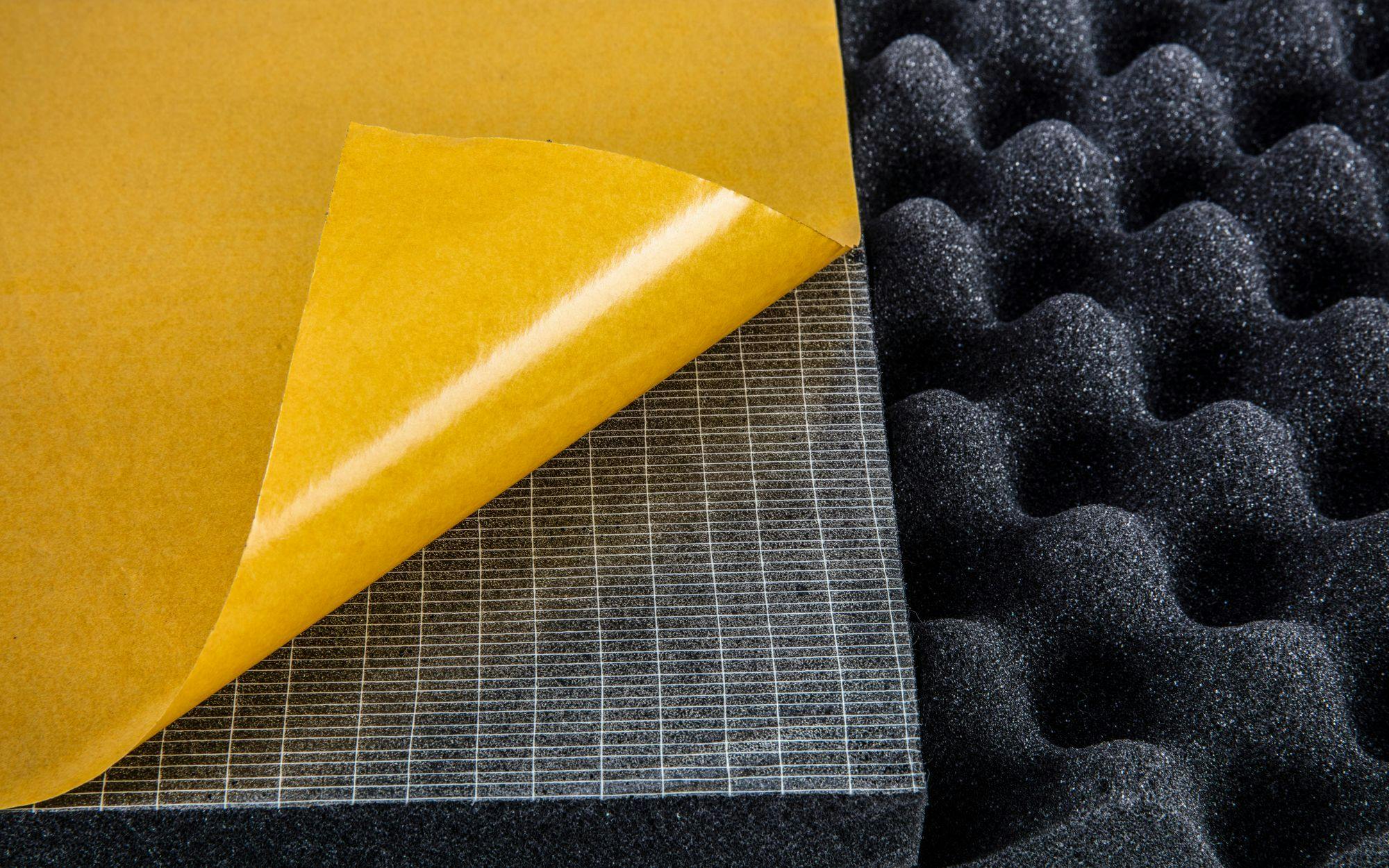

However, thanks to advances in material science technologies, soundproofing options have recently moved toward more viable and cost-effective solutions. In particular, the composite manufacturing and polymer chemistry fields have allowed the development of promising new alternatives that can replace costly layers of gypsum. Among these materials are a range of unique soundproofing membranes that cater to different needs and installation scenarios, including Tuff-Mass, Acoustiblok, Mass Loaded Vinyl and Wall Blokker. All of these products have individual benefits and applications.

The cost savings of these soundproofing alternatives are particularly seen with membrane products made from upcycled and recycled materials. In addition to their environmental benefits, recycled materials can be 30% to 40% less expensive than virgin materials. When compared apples-to-apples, there are many situations in which soundproofing products may be used at a significant cost reduction to extra layers of drywall.

For example, when achieving STCs of 50 or higher, at least a third layer of drywall will be needed, or a layer of sound attenuating material. A wall with two layers of drywall on each side can achieve an STC of 54 (with optimal stud spacing and gauge), but the same wall with a single layer of drywall on each side and one total layer of soundproofing membrane can achieve STCs of 56 and higher. With the increased cost of drywall, many membranes can be installed at half the cost and with significant schedule savings.

While the cost and time benefits of soundproofing membranes are clear, they tend to be frequently overlooked due to design misconceptions.

For example, many walls are designed at 16 inches on center studs, when wall heights or structural usage do not dictate that as a requirement. While counter intuitive to many, a wall with studs at 24 inches on center blocks significantly more noise than one with studs at 16 inches on center. That’s because as studs are placed closer together, the wall increases in stiffness, allowing additional sound to transmit through the studs.

Likewise, 25-gauge studs are much more effective a dampening noise transfer due to their flexibility than a corresponding 20-gauge stud wall, and both are better than a wood stud wall—even if two-by-six studs are used.

By using stud spacing and gauge to your advantage, significant cost savings may be realized. Building a wall with 25-gauge studs at 24 inches on center can still achieve wall heights of 12 feet or higher, with seven to nine more STC points than a corresponding wall, and with greatly reduced cost and schedule.

Achieving more STC points is particularly important when the future space or tenant occupancy is undetermined. It is generally less expensive to design for a higher STC adjacency than to retrofit a solution afterward. This happens commonly when a spa, salon or other low-ambient noise location is placed next to a fitness facility. After-market remediations are much more expensive and, on the whole, less effective.

The future and economic sustainability of commercial soundproofing depends on the implementation of new innovative materials and the industry’s understanding of their applications and cost-benefit ratios. A partition can be built for higher STCs with new materials at a lower cost than ever achieved with conventional methods. When unsure, engage an acoustical engineer or consultant to audit your wall design, and then perform a field test on a mock room to determine the performance of the assembly.

Related stories