This is the second in a series of sit-down interviews with Matt Abeles, ABC’s vice president of construction technology and innovation. Discover where the industry stands on a variety of technologically focused topics at the height of current events.

Construction Executive: Is anything excluded in “robotics” to you?

Matt Abeles: You have a big hardware component to robotics, but I don’t think something like artificial intelligence would be an exclusion of that. It’s just a smaller component of AI that is included.

CE: Was robotics an up-and-coming field prior to the advent of COVID-19?

MA: I think robotics was up-and-coming. Like many technologies, robotics was in play on a very small number of sites in 2015 and 2016. Now, when you look at the changing workforce, the increased pressure to keep jobsites safe and make jobs smarter was born on smart devices. I think there has been a huge change as it relates to the pandemic.

CE: Is there a real market for robotics at the moment? Or is interest more experimental at this point?

MA: I think there’s high interest. As it becomes more adopted, it will get cheaper, but if you’re looking at cost, that probably concerns mid-sized to larger contractors.

I would say that the interest is definitely more than experimental. It’s being used on real jobsites across the country—there’s no doubt about that. One of the most widely-known players in this space is Construction Robotics and, as just one of the companies in the space, they’ve been deployed on many projects and the trend is positive. As the need to be more efficient and cost-conscious increases, I think robots will become more and more prevalent.

CE: Do people need to be wary of robotics replacing jobs or taking over the workforce?

MA: No, it’s not taking over the world Terminator-style. Robotics is not “taking jobs,” because a robot cannot do every single piece of work a building requires.

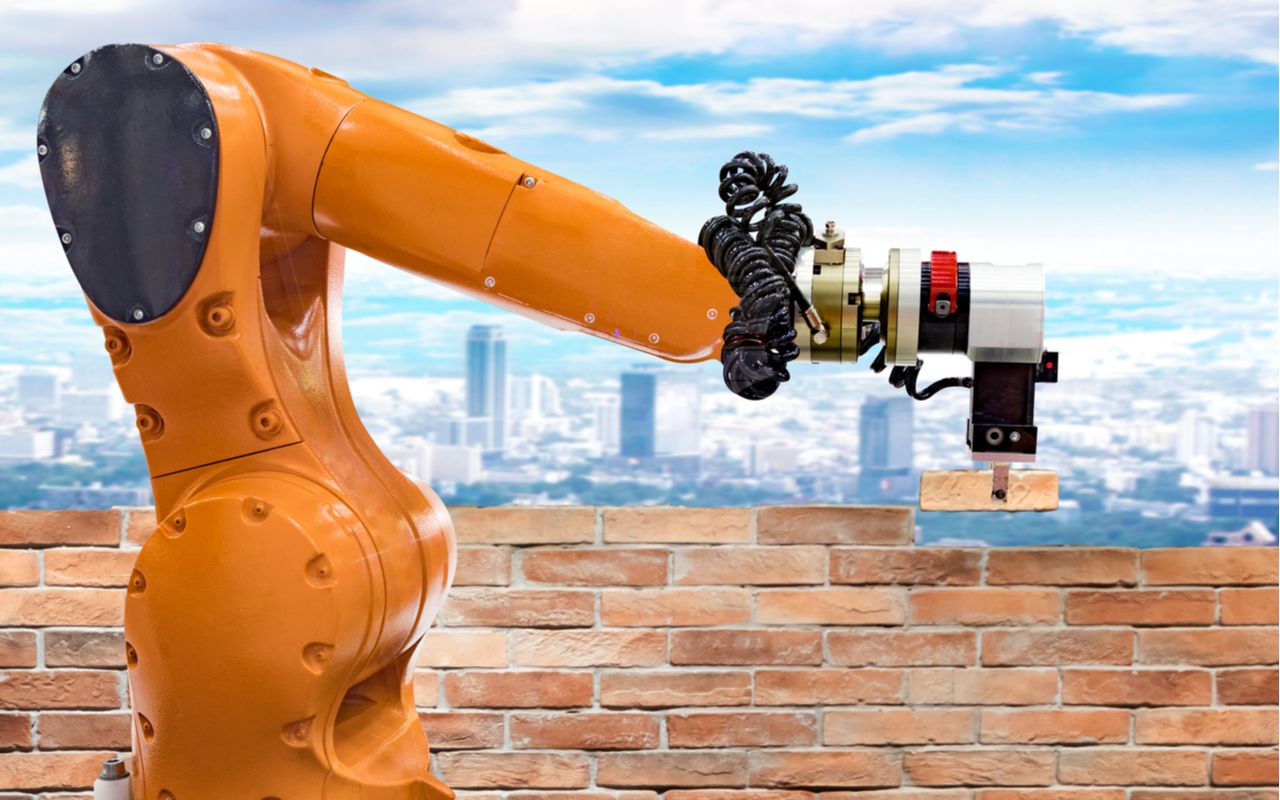

Robots lay bricks, carry larger objects that it might be unsafe to lift and, in a time where fewer people are able to be on a jobsite, it’s more relevant to increase safety, productivity and ROI.

Especially when you’re looking at attracting new talent, robotics attracts a younger, more tech-savvy workforce, which can be difficult in construction.

CE: It sounds like one of the most attractive features, for you, is the safety component, correct?

MA: Absolutely. As an industry, we’re trying to move towards being one of the safest in the country. Robotics has a lot of advantages, but the safety component is huge; even if everything else was equal (like costs or number of employees), but the jobsite was safer with the use of robotics? I would use it every time.

CE: What are the top ways you anticipate this field changing construction in the future?

MA: I think robotics will help with the issue of attracting talent. The technology is going to improve and there will be more robots on jobsites. People are so focused on 3D printing buildings, but there will be more buildings built by robots than are 3D printed. I think that’s a misconception by many in the space right now.

In addition, jobs will evolve like in any industry. There are always going to be workforce development and apprenticeship programs. But the jobs are going to get smarter and the education is going to change.

I think we’re going to catch up with other industries and that this is one way we’re going to do it.

CE: So if you had to bet on a future technology (3D printing, VR, AI or robotics) you would bet on robotics?

MA: I would. Robots that build structures—whether for buildings, bridges or panels for prefabricated components—are here to stay. It’s a field that covers many of the areas we need to improve in construction and you’re going to see more in the realm of robots helping the construction process.