Three Strategies for Building Products Manufacturers to Address the Workforce Shortage

Ten years after the Great Recession, the construction industry still struggles with a workforce unable to keep up with demand. Many skilled workers left during the financial crisis and never came back.

Construction industry statistics reflect this and point to a future indicating more of the same—even with the increase in housing starts and surge in building permits. For instance, while employment in the construction sector has increased since 2011, the number of construction sector employees is still below pre-recession levels: around 7.15 million in March of 2018, compared with 7.7 million in April 2006, according to U.S. Labor Bureau statistics. Unemployment numbers in the industry bear the same trend: This year’s average of roughly 7 percent unemployment is almost four times lower than the 2010 high.

On whom does the labor shortage burden weigh most heavily? General contractors, with most confirming that they are facing a worker shortage. In a national survey, the Association of General Contractors found 70 percent of construction companies were having a difficult time filling subcontractor and other trade positions such as bricklayers, carpenters, roofers and electricians, which represent the bulk of the construction workforce. Almost two-thirds surveyed said it would continue to be difficult, or even become more difficult, to hire.

Fortunately, the labor shortage does present some opportunity. While the construction industry workforce is struggling to keep up with demand, manufacturers and other industry stakeholders can help ease the burden. Here are three strategies for manufacturers and other industry entities to consider in making a welcomed difference in the construction industry.

1. Remove hassles and make the most of their time.

Consider that the industry’s shortage of labor is about a shortage of time. Builders, contractors and specifiers still don’t have enough hours in the day to get their work done. Manufacturers of building products can help by offering products, services and support to help their buyers get the most out of their time.

To do this, organizations should look for ways to reduce hassles for buyers. Smooth out the process of buying, managing and using building products to help builders and specifiers make the most of every hour on the jobsite, which will ultimately lead to increased sales and long-term loyalty.

2. Provide vocational and training support.

By looking at the current demographics of the construction industry’s workforce, one can see there’s opportunity to address evident disparities. The “mass exodus” of the Great Recession has shown light on the need to take stock of who is comprising the industry today—and who isn’t.

According to a 2017 Brookings Institution report, 20 percent of those employed in the construction industry in 2015 were low-skilled immigrants, with 12 years of education or less. Today’s construction workers may be less experienced than their pre-recession counterparts, so it’s likely that a significant number of workers could benefit from additional training. Manufacturers and other entities can take the lead in providing training and restoring trust in the industry through sponsorship of vocational training or information sessions. Vocational training may also help to recruit new workers to the industry by knocking down some of the barriers to entry.

Along with establishing additional training, there’s a need to change the perception around the current image of construction work. Assumptions that it’s dangerous, low-paying work with few benefits and little opportunity for career advancement must be challenged. Manufacturers—through efforts to affect perception in messaging, marketing and technology—are poised to do so.

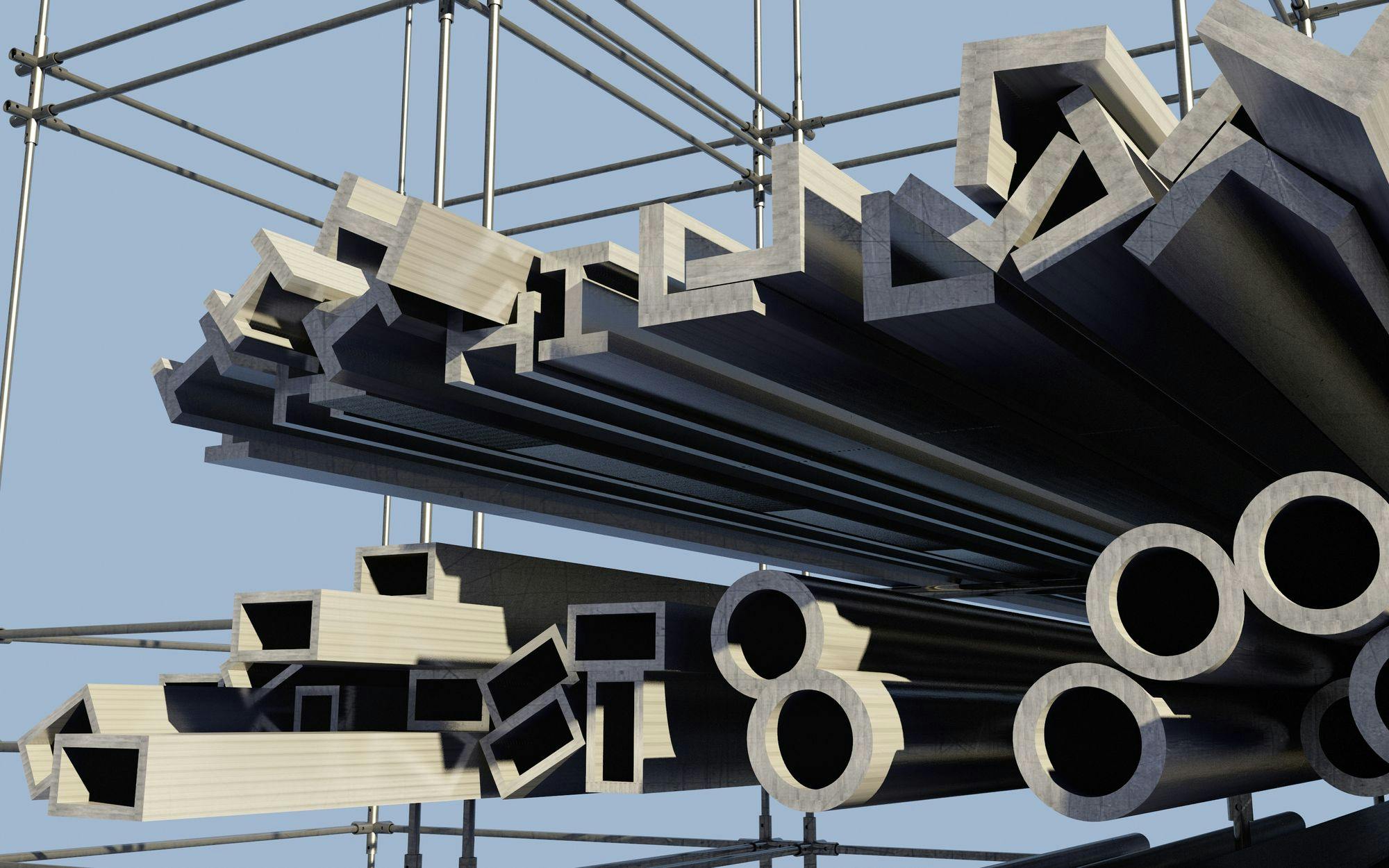

3. Engineer products to work harder and add efficiency in support

Lastly, product innovation is another tool manufacturers can use to help ease the construction industry labor shortage. Engineering products to be easier to handle and install could go a long way to reduce work complexity and the number of construction workers required. Introduce a lighter, easier-to-carry product or packaging option. Remove the friction inherent in buying, selling and using the products by adding a quick re-order and delivery option for a bundle of commonly used materials. Or, host a series of webinars or workshops on how to order, measure or install the product.

Along with re-engineering products, save builders time by rethinking the marketing, sales and technical support behind products and how they add efficiency. Consider how an organization’s sales people, technical representatives and internal marketing experts can provide increased support and productivity. Analyze everything from your product portfolio, to your marketing efforts, sales strategies and technical support for opportunities in efficiency between builders, contractors and specifiers.

In a time where builders and contractors have fewer skilled workers but more work, it’s important for building products manufacturers to be on the lookout for anything that can save construction industry professionals time, grow vocational interest in the construction trades and provide support that ultimately, can even increase sales.

Related stories